The rusty supply chains of the past have little to no bearing on the future as Southeast Asia shifts towards realising its vision for Industry 4.0. The world over, operational processes are becoming more digitised, transparent, connected and highly efficient.

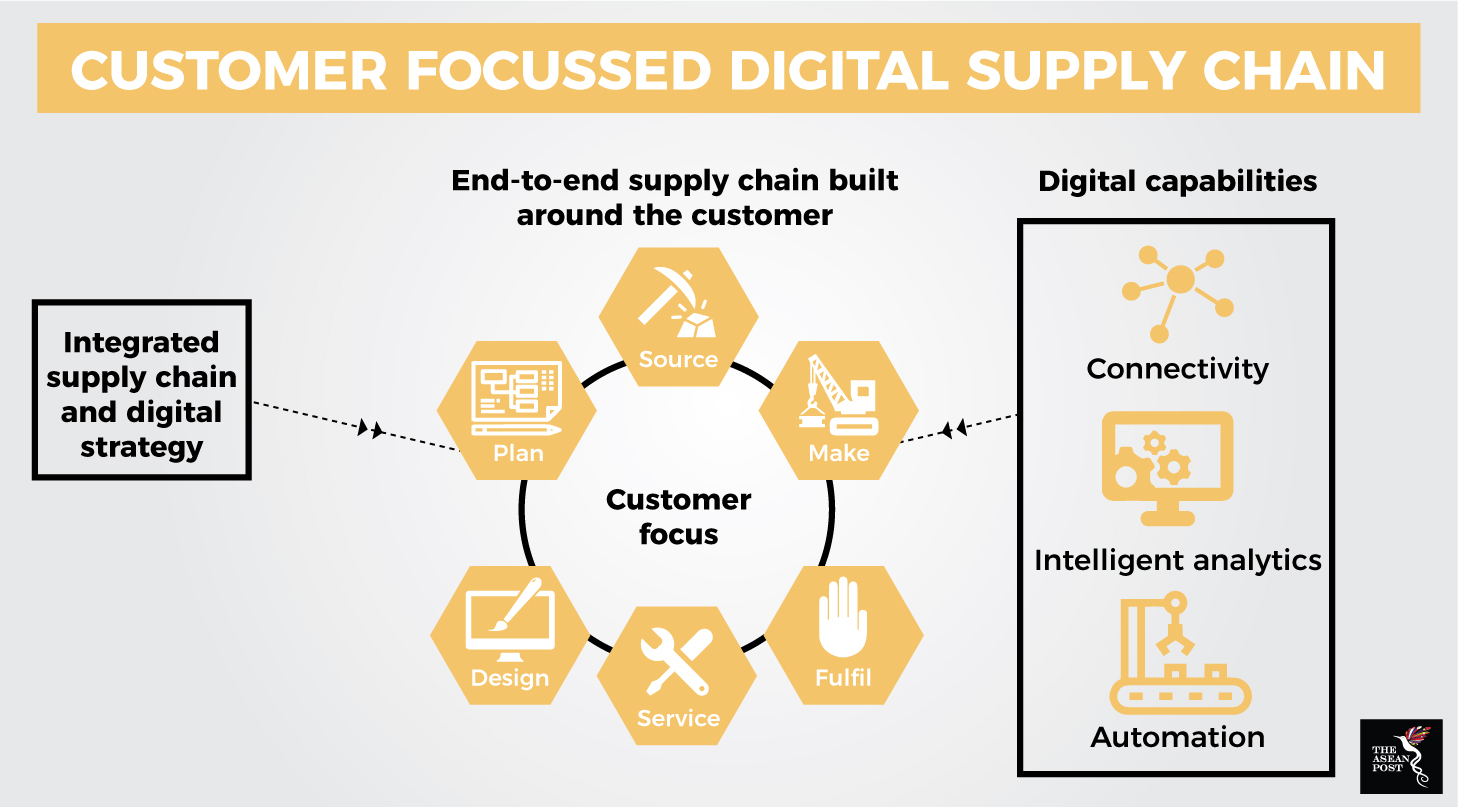

A digital supply chain (DSC) relies on several key elements like integrated planning and execution systems, autonomous logistics and smart procurement. What underpins these components are advancements in new technologies such as cloud computing, big data analytics and the Internet of Things (IoT).

A DSC is favourable for a highly complex market like ASEAN’s which is laden with operational inefficiencies, supply-side challenges and demanding consumer requirements. Through the use of technology, a DSC will allow for the right product to be delivered to customers quickly and reliably while ensuring efficiency via automation. Thus, it will allow for companies operating within the region to gain a competitive advantage over others and become more resilient to changing global conditions.

Who benefits?

Businesses and consumers stand to gain most from a digitalised supply chain. For businesses, the primary advantage is process improvement led by automation. For example, using advanced analytics for demand planning and smart warehousing can increased productivity and operational efficiency. Subsequently, it would greatly reduce operation costs.

Besides that, end-to-end visibility of the DSC provides a bird’s eye view of every aspect of the supply chain thus allowing for greater supply chain transparency and collaboration amongst partners. When information is readily and rapidly available, decision-making can occur faster and ad hoc real-time planning can take place in response to changes in demand or supply. As a result, the supply chain can work with greater flexibility and efficiency.

Agile DSCs can help boost customer experiences as companies will be better equipped to foster closer relationships with consumers. A digitally enhanced supply chain would also be able to cater to customisation requests as well as reduce lead times and out-of-stock scenarios, thus improving service levels. Subsequently, it would result in greater customer satisfaction and ultimately customer loyalty.

Traceability and transparency

In today’s world, businesses are increasingly in the spotlight with regards to the safety and integrity of their product manufacturing processes. Opaque supply chains expose companies to a myriad of risks including allegations of unethical labour practices and raw material sourcing as well as low factory safety standards to name a few.

Source: Accenture

Hence, the traceability – from raw material sourcing to product completion – of the supply chain is of paramount importance from both, ethical and business perspectives. Bad practices affect people and can harm the environment. The knock-on effect this has on a brand’s reputation and image can also have long lasting implications.

Given such a situation, DSC’s must take advantage of the latest in technological advancements like blockchain technology which is fast revolutionising supply chains the world over. Blockchain is a shared ledger of all the activities related to a particular product. All relevant parties have access to this information with no one party having control of it. Blockchain decentralises the system and makes it more reliable. A blockchain-enabled system allows for the digital tracking of product information in a supply chain, including origination details, batch numbers, factory and processing data, expiration dates and storage temperatures, as well as shipping details.

Although blockchain may still be at a nascent stage of development with regards to supply chain logistics, it nevertheless represents a tremendous opportunity for the sector to provide precise and granular visibility of products as they go through the many stages of production compared to existing technologies such as RFID tagging.

Moreover, it affords a stricter auditability which results in higher standards of quality in terms of production and distribution. Subsequently, it reduces the risk of retailers selling and consumers purchasing products that are unsafe, sourced unethically and manufactured using unsustainable practices.

A blockchain engineered solution would help drive greater collaboration and trust between supply chain partners.

According to Philip Chu, Managing Director of the Global Centre of Excellence, a supply chain consultancy set up by global logistics company DHL, technology is a key driver which would further facilitate breakthroughs in supply chains of the future.

“Leveraging on the latest innovations and IoT, we have access to data and information that did not exist in the past and can now be used to increase efficiency in the warehouse environment and the potential end to end value chain," he said.

The key is how to define and translate these data into solutions that provide meaningful insights, delivering business values and impact to the industry,” explained Philip.