The Vietnam Textile and Apparel Association (VITAS) and World Wildlife Fund (WWF) Vietnam are collaborating to transform Vietnam’s bourgeoning textile and apparel industry into a more sustainable one. The project was launched this month and will be carried out from 2018 to 2020. It will involve engaging the sectoral players to better manage their water and energy use – focusing specifically on the Mekong and Dong Nai deltas, where more than half of Vietnam’s apparel factories are located.

The project also targets raising the sustainability profile of Vietnam’s textile and apparel industry by introducing better river basin governance to improve water quality. This is expected to bring about social, economic, and conservation benefits to the country. It follows a similar project funded by HSBC Bank to reduce the impact of the textile industry along the value chain in China, Bangladesh, India and Vietnam.

According to VITAS’ Chairman, Vu Duc Giang, the project is timely as it reinforces the need for better management of the textile and apparel industry by holding it to higher environmental and social standards. This is parallel to the increasing awareness of customers worldwide who demand global brands to become more ethical in their business practices.

"Vietnam ranks as the fifth largest exporter of apparel goods in the world but our industry is more famous for low-cost production with limited environmental standards. If we do not change our practice now, Vietnam could lose its competitiveness. That is why this project is so important and timely," he said.

"In the long run we want to see factories, industrial parks and other actors come together to take more proactive collective actions to address risks and impacts beyond their factory fences and more responsibly manage shared resource uses across-sectors," said WWF-Greater Mekong’s Water Lead, Marc Goichot.

Environmental footprints

Taking advantage of their young population, low-cost labour, and natural resources, countries such as Cambodia, Lao PDR, Myanmar and Vietnam have targeted investments in the textile and apparel industries.

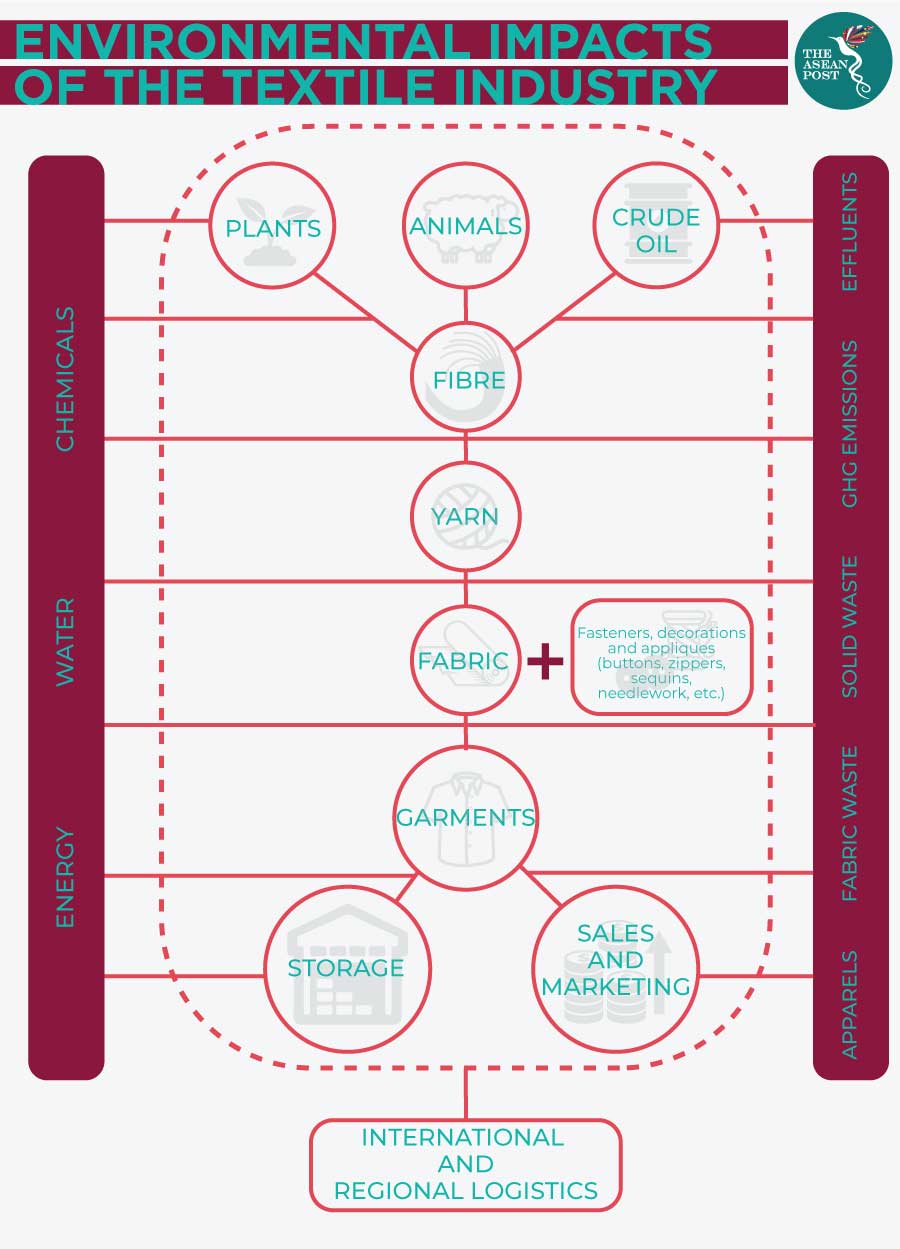

The textile industry however, consumes a lot of energy and water in its operations throughout the value chain and along the products’ lifecycle. The consumption of energy and water takes place in the processing of the raw materials all through to the production stage. This overconsumption is also seen in the logistics, sales and marketing of the products.

Other factors can also affect how much energy and water is consumed. Different fibres – whether they are made from renewable materials such as cotton, bamboo and silk or non-renewable sources like petroleum – have different water and energy footprints. For example, polyester fabrics which are made from petroleum consume over 70 percent of the total energy used at the production phase. For cotton products, most of the energy consumption occurs during the post-retail phase by consumers. In terms of water usage, cotton is one of the most water-intensive agricultural crops.

Energy consumed by the textile industry raises the national greenhouse gas (GHG) levels and because of this, the industry is seen as one of the main drivers of climate change. Meanwhile, the water footprint during these processes include overconsumption and release of improperly treated or untreated chemical effluent into waterways. The industry is also responsible for generating solid waste such as fabric waste.

Chinese greening efforts

In the face of domestic environmental issues such as having rivers that are too polluted for human contact, water scarcity and air pollution, China has recently adopted greening measures for its own textile and apparel industry. The country is responsible for more than 50 percent of the world’s fabric. According to a report by United States (US) based Natural Resources Defense Council (NRDC), 33 Chinese textile mills serving brands such as Levi Strauss, H&M, Target and Gap are collectively saving US$14.7 million annually by adopting simple greening and efficiency measures.

With increased consumer awareness of ethical and environmental standards, enterprises will need to improve their practices or lose out to global competition. The introduction of greening measures that will give Vietnam a leg up over the rest of the world will require additional commitment from the authorities and industry players. However, with Chinese businesses leading the way, it will surely make the transformation easier to swallow.

Related articles: