Kenaf is a plant that most people may not have heard about but is used to produce many types of eco-friendly materials. These materials are already being used by most of us unknowingly on a daily basis.

From paper to furniture and from biofuel to textiles, kenaf (Hibiscus cannabinus L) has been grown for over 3,000 years and can be harvested in just four to five months, alleviating the shortage of forest based raw materials and countering deforestation. United States (US) Department of Agriculture studies show that the yield from kenaf – a plant which is similar to hemp, jute and flax – are generally three to five times greater than that of most trees, which can take from 10 to 20 years to reach harvestable size.

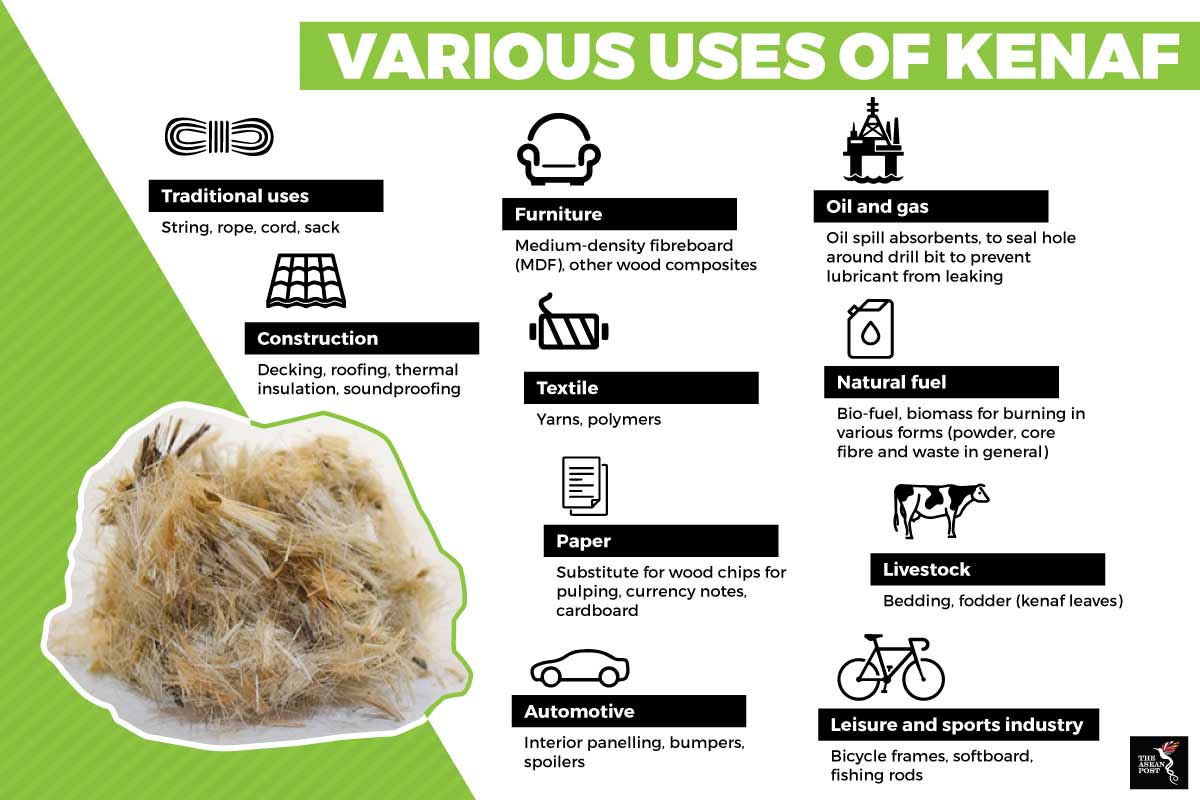

Kenaf is a major crop in Africa and Asia, where it is used for various cordage products such as rope, twine and burlap. In construction, it is used for thermal insulation of walls, floors and roofs and soundproofing solutions, while in furniture, is it used in the manufacturing of medium-density fibreboard (MDF) and other wood composite materials.

Globally, the demand for natural fibres such as kenaf is growing at 10 to 15 per cent annually – especially for use in composite material. China, Bangladesh, Thailand and Myanmar contribute 95 percent of global kenaf production which totals three million tons a year, although there are no definitive statistics surrounding the cultivation, use and trade of kenaf in ASEAN.

In Malaysia, kenaf is fast becoming the country’s third industrial crop after palm oil and rubber after first being introduced in 2010 as an alternative to tobacco.

The National Kenaf and Tobacco Board of Malaysia has allocated 2,000 hectares for smallholders to cultivate kenaf – the global market of which is expected to reach US$854 million by 2025.

Last October, Malaysia’s Primary Industries Minister Teresa Kok said the kenaf industry has great potential to be developed as a new economic source, but the government needs the support of the private sector to further develop the industry.

In 2017, Filipino Congressman Salvador Belaro Jr. called for increased research and application of kenaf to counter the effects of climate change and global warming – describing it as an “in-demand societal investment”.

“Kenaf absorbs more carbon dioxide from the atmosphere than any other crop. Every hectare of kenaf consumes 30-40 tons of carbon dioxide during each growing cycle. During a single growing cycle, each hectare of kenaf consumes the same amount of carbon dioxide which 20 cars emit in one year,” he said.

In Thailand, kenaf was the second most farmed product after rice and reached a high of 352,000 hectares (yearly average) in the mid-sixties. However, the lack of global demand in the 1970s led to farmers switching to other crops that produced profits such as cassava, corn and sugarcane.

Source: Various

Uses in the automotive, oil and gas industry

Kenaf’s use as biofuel and its ability to replace oil-based materials – and its low cost compared to synthetic glass and carbon fibres – has caught the attention of several automobile companies.

Apart from praising kenaf for its sustainability, they are also fans of its ability to reduce vehicles’ weight, and thus, fuel consumption.

Toyota has been using kenaf for automotive interiors since the mid-1990s and components using kenaf are in 27 of its high-end vehicle models. In the BMW i3 electric car for example, door panelling and the instrument panel cover is made of a kenaf composite. Kenaf also makes up 50 per cent of the materials inside the door of the 2013 Ford Escape, making for a lighter-weight and greener vehicle solution.

“Kenaf and the other renewable materials in the Escape have made the vehicle more environmentally friendly and fuel efficient,” said Laura Sinclair, materials engineer for Escape.

Studies by the US Department of the Navy have identified kenaf as one of the world’s most natural absorbent materials, leading to its use in the oil and gas sector.

US-based Hemp Inc. has introduced a kenaf and hemp-derived well drilling product, DrillWall, to seal the hole around drill bits to prevent the drilling lubricant from leaking into cracks or other porous formations in the earth around the drill hole. The company also produces another kenaf product which was used to help clean up the oil spill in the Gulf of Mexico after the BP Deepwater Horizon offshore oil rig exploded in 2010.

Securing long-term contracts with American oil field drilling and production companies, Hemp Inc. has also sold samples of DrillWall for testing to global giants such as Saudi Aramco, the Kuwait Oil Company, Pemex (Mexico), Petrobras (Brazil) and ConocoPhillips, among others.

“It’s such a green solution for the drilling industry it’s not even funny,” said Hemp Inc. CEO Bruce Perlowin.

“In 12 to 24 months, we’ll be manufacturing it 24/7, three shifts a day. Once they see the product, once they test it, they’ll want it. Now that they know that we’re out there, we’ll be all over the place,” he added.

Kenaf may already be “all over the place”, but more research and investment is needed for ASEAN countries to capitalize on the economic and environmental benefits of this wonder plant.

Related articles:

Fighting deforestation with technology

The tides are changing in favour of renewable energy

The Balikpapan oil spill could have long-term effects